Manufacturing Process / Machining Process

Magnets that have been through the sintering process are machined and plated.

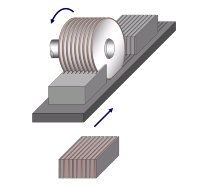

Due to shrinkage from the sintering process, required measurements are achieved by grinding the magnets with abrasives.

Diamond abrasives are used for this process because the magnet is very hard.

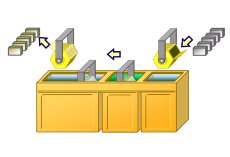

To best suit the environment in which they will be used, the magnets are subject to various surface treatments.

Nd-Fe-B magnets are generally susceptible to rust so they are surface treated with nickel or paint. Sm-Co magnets have a high resistance to corrosion so they are not usually plated.

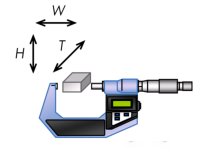

Magnets that have been machined and plated are measured and visually inspected. In addition, magnetic properties, corrosion and maximum energy are tested to specifications.

Magnets that have been machined and plated are measured and visually inspected.

In addition, magnetic properties, corrosion and maximum energy are tested to specifications.

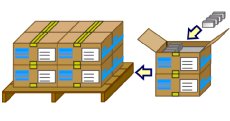

Magnets that have passed product testing are packaged and shipped. Flux leakage shields are utilized for air shipment when required.

Shin-Etsu Chemical's magnetic products are shipped in Japan and to worldwide customer manufacturing locations